پولات يوپۇق تۈۋرۈكى قۇرۇلۇش ۋە قۇرۇلۇش قۇرۇلۇشلىرىدا تۇپراقنى كۈچلۈك ساقلاش ۋە سۇ ئۆتمەس توساقلارنى تەمىنلەش ئۈچۈن ئىشلىتىلىدىغان، ئۆزئارا باغلىنىشلىق، ئالدىن ياسالغان پولات بۆلەك بولۇپ، قۇرۇلۇش تاملىرى، توسۇقلار ۋە سۇ بويى قۇرۇلمىلىرىنى ياساشقا ئىشلىتىلىدۇ.

ئىسسىق دومىلىتىلغان 6/9/12 مېتىر ئۇزۇنلۇقتىكى U شەكىللىك سۇ توختاتقۇچ پولات يوپۇق تام زاۋۇتى

مەھسۇلات ئىشلەپچىقىرىش جەريانى

ئىشلەپچىقىرىش جەريانىQ235 پولات يوپۇق تۈۋرۈكلىرىئادەتتە تۆۋەندىكى قەدەملەرنى ئۆز ئىچىگە ئالىدۇ:

خام ئەشيا تەييارلاش: ئىسسىق دومىلىتىلغان پولات تاختىلارنى ئىشلەپچىقىرىش ئۈچۈن خام ئەشيا قىلىپ تەييارلاڭU شەكىللىك پولات تاختىلار.

قىزىق دومىلاش: Q235 پولات يوپۇق دۆۋىلىرى قىزىق دومىلاش زاۋۇتىغا ئەۋەتىلىدۇ، ئۇ يەردە ئالدىن ئېگىلىپ دومىلاش ئارقىلىق U شەكىللىك كېسىشمە شەكىل ھاسىل قىلىنىدۇ.

كېسىش: U شەكىللىك پولات يوپۇق تۈۋرۈكلىرى كېسىش ئۈسكۈنىلىرى ئارقىلىق خالىغان ئۇزۇنلۇقتا كېسىلىدۇ.

سوغۇق ئېگىش: پولات يوپۇق تۈۋرۈكلىرى تەلەپ قىلىنىدىغان چوڭلۇق ۋە شەكىلگە ماس كېلىشىگە كاپالەتلىك قىلىش ئۈچۈن سوغۇق ئېگىلىدۇ.

تەكشۈرۈش ۋە سۈپەت كونترولى: تەييار مەھسۇلاتلارنىڭ ئالاقىدار ئۆلچەم ۋە ئۆلچەملەرگە ماس كېلىشىگە كاپالەتلىك قىلىش ئۈچۈن تەكشۈرۈلىدۇ.

ئوراپ قاچىلاش ۋە توشۇش: تەييار مەھسۇلاتلار ئوراپ قاچىلىنىپ، خېرىدارغا ياكى قۇرۇلۇش ئورنىغا يەتكۈزۈلىدۇ.

بۇ باسقۇچلار ئىشلەپچىقىرىش جەريانلىرى ۋە ئۈسكۈنىلىرىنىڭ ئوخشىماسلىقىغا ئاساسەن ئوخشىماسلىقى مۇمكىن، ئەمما ئادەتتە ئىشلەپچىقىرىش جەريانىنىڭ ئاساسىي باسقۇچلىرىدۇر.قىزىق دومىلىتىلغان U شەكىللىك پولات يوپۇق دۆۋىلىرى.

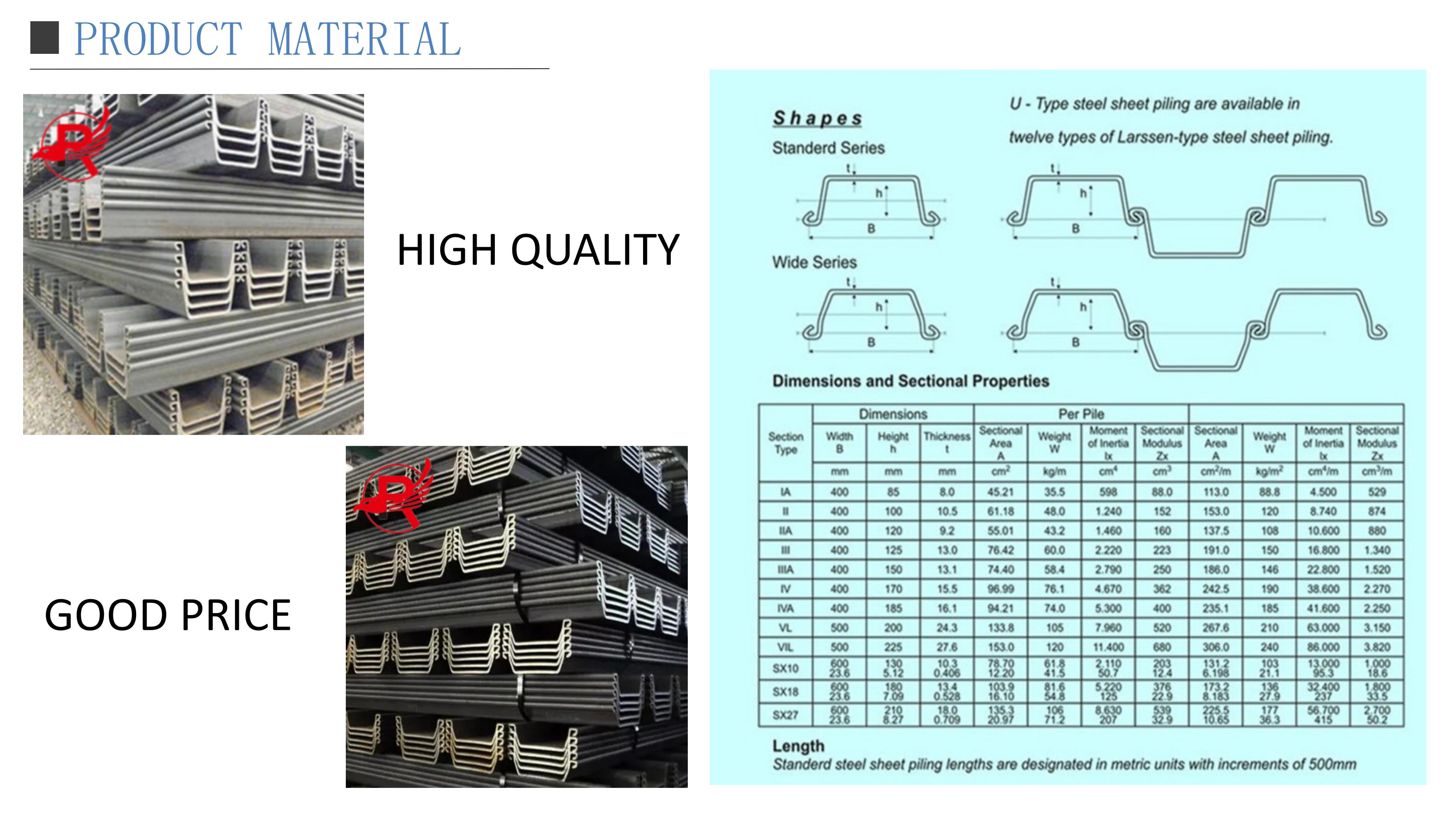

| ئۈچۈن ئۆلچەملەرU يوپۇرماقلىق قەغەز ئۈيمىسى | |

| 1. چوڭلۇقى | 1) 400*100مىللىمېتىر، 500*200mm,600*360mm |

| 2) تام قېلىنلىقى:4—16MM | |

| 3) U تىپلىق يوپۇرماق ئۈيۈم | |

| 2. ئۆلچەملىك: | GB/T29654-2013 EN10249-1 |

| 3. ماتېرىيال | Q235 Q235B Q345Q345B S235 S240 S270 S275 SY295 S355 S340 Sy390 Nz14 Au20 Az36 Pz12 Pz18 Pz27 |

| 4. زاۋۇتىمىزنىڭ ئورنى | تيەنجىن،جۇڭگو |

| 5. ئىشلىتىش: | 1) ھەرىكەتچان ۋاگون |

| 2) پولات قۇرۇلما قۇرۇش | |

| 3 كابېل تەخسىسى | |

| 6. قاپلاش: | 1) يالىڭاچلانغان2) قارا رەڭ بىلەن بويالغان (لاك قاپلاش)3) گالۋانلانغان |

| 7. تېخنىكا: | قىزىق دومىلىتىلغان |

| 8. تىپى: | Uتىپىدىكى يوپۇرماق دۆۋىسى |

| 9. بۆلەك شەكلى: | U |

| 10. تەكشۈرۈش: | خېرىدارنىڭ تەكشۈرۈشى ياكى ئۈچىنچى تەرەپ تەرىپىدىن تەكشۈرۈش. |

| 11. يەتكۈزۈش: | كونتېينېر، چوڭ تىپتىكى پاراخوت. |

| 12. سۈپىتىمىز ھەققىدە: | 1) بۇزۇلۇش يوق، ئېگىلىش يوق 2) مايلاش ۋە بەلگە قويۇشقا بولمايدۇ 3) بارلىق ماللارنى توشۇشتىن بۇرۇن ئۈچىنچى تەرەپ تەكشۈرۈشى ئارقىلىق تەكشۈرگىلى بولىدۇ |

مەھسۇلات چوڭلۇقى

*ئېلخەتنى بۇ ئادرېسقا ئەۋەتىڭ[email protected]لايىھەلىرىڭىز ئۈچۈن باھا ئېلىش

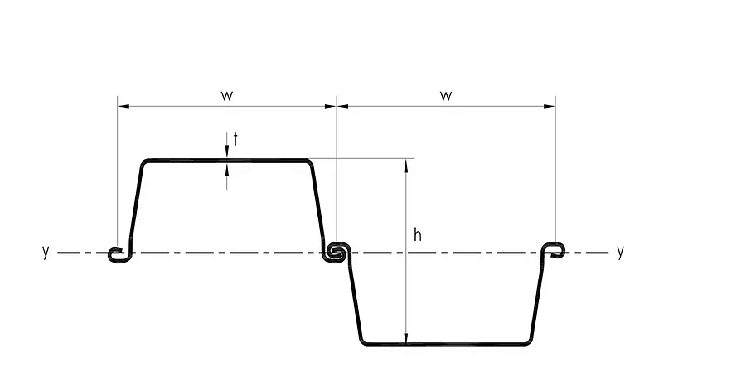

| بۆلۈم | كەڭلىك | ئېگىزلىكى | قېلىنلىقى | كېسىشمە كۆلىمى | ئېغىرلىقى | ئېلاستىك بۆلەك مودۇلى | ئىنېرتسىيە مومېنتى | قاپلاش كۆلىمى (ھەر بىر ئۈيۈمنىڭ ئىككى تەرىپى) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (ھ) | فلانس (tf) | تور (tw) | ھەر بىر ئۈيۈمگە | ھەر بىر تامغا | |||||

| mm | mm | mm | mm | سانتىمېتىر²/مېتىر | كىلوگرام/مېتىر | كىلوگرام/كۇۋادرات مېتىر | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2000 | 49,026 | 2.38 |

بۆلەك مودۇلى دائىرىسى

1100-5000cm3/m

كەڭلىك دائىرىسى (يەككە)

580-800 مىللىمېتىر

قېلىنلىق دائىرىسى

5-16 مىللىمېتىر

ئىشلەپچىقىرىش ئۆلچىمى

BS EN 10249 1- ۋە 2-قىسىم

پولات دەرىجىسى

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42، Gr50، Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

باشقىلار تەلەپ بويىچە تەمىنلىنىدۇ

ئۇزۇنلۇقى

ئەڭ كۆپ بولغاندا 35.0 مېتىر، لېكىن ھەر قانداق لايىھەگە خاس ئۇزۇنلۇقتا ئىشلەپچىقىرىشقا بولىدۇ

يەتكۈزۈش تاللانمىلىرى

يەككە ياكى جۈپ

جۈپلەر بوش، كەپشەرلەنگەن ياكى قىسىلغان بولىدۇ

كۆتۈرۈش تۆشۈكى

تۇتۇش تاختىسى

قاچى ئارقىلىق (11.8 مېتىر ياكى ئۇنىڭدىن كىچىك) ياكى توپ تارقىتىش

چىرىشتىن ساقلىنىش قاپلىمىلىرى

ئالاھىدىلىكلىرى

قاتتىق تۇپراق، سىلانت ۋە قاتتىق شېغىل قاتارلىق گېئولوگىيەلىك قۇرۇلما مۇھىتىدا، پولات يوپۇق تۈۋرۈكلىرىنىڭ سوقۇلۇشى ۋە تىترىشى كىچىك، قۇرۇلۇش تېخىمۇ قىيىن، قۇرۇلۇش ئۈچۈن تېخىمۇ ئىلغار ئۈسكۈنىلەر تەلەپ قىلىنىدۇ.

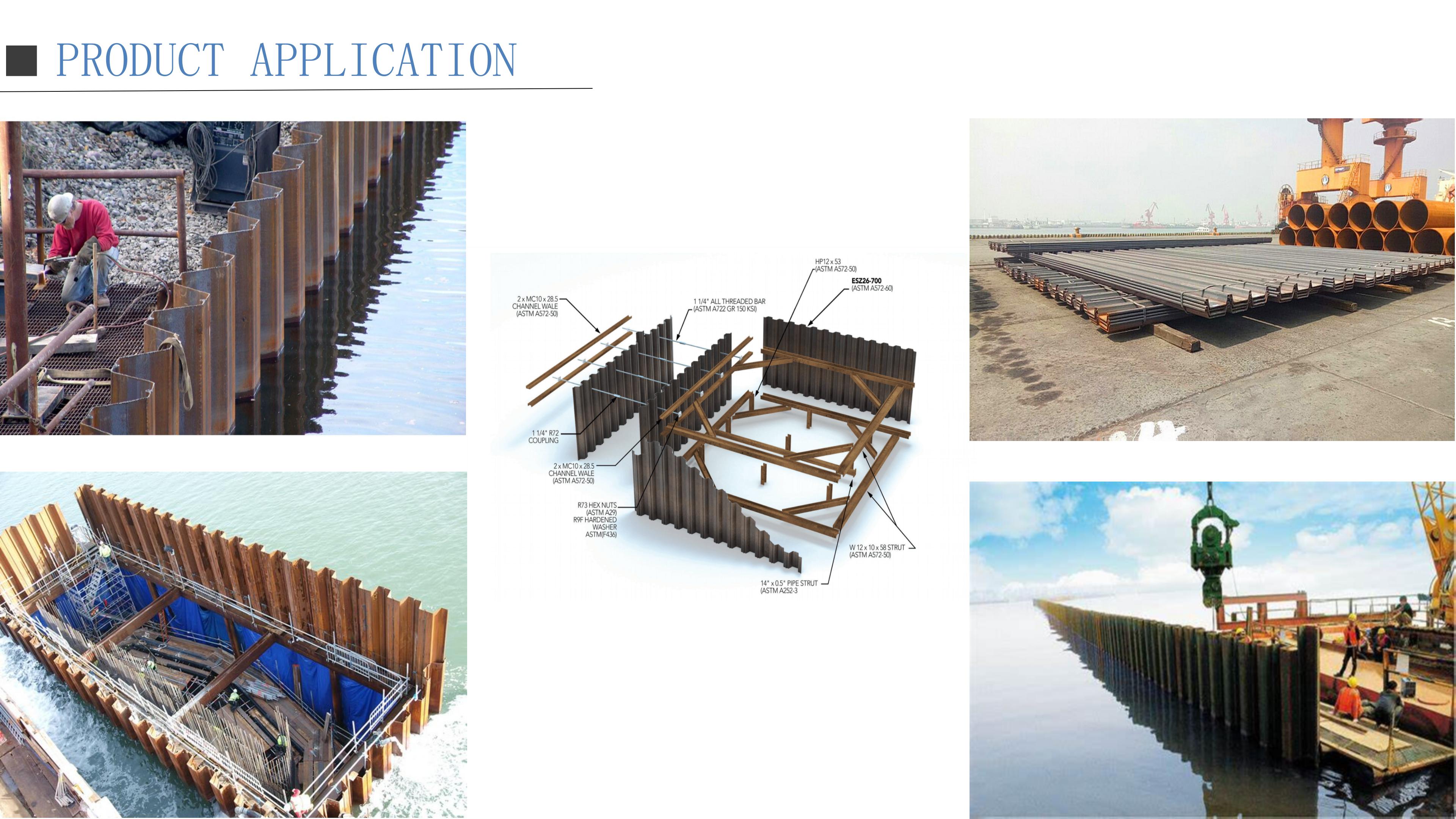

قوللىنىش

مېتال يوپۇق قەۋەتلەشچوڭقۇر لاي قەۋىتى، نەم ۋە سۇ ئاستى مۇھىتىدا ئاساسنى تىرەپ تۇرۇشتا تېخىمۇ ياخشى ئۈنۈم بېرىدۇ. قۇرۇلۇش سۈپىتىگە كاپالەتلىك قىلىش ئۈچۈن، سوقۇش ۋە تىترەشنىڭ كۈچلۈكلۈكى ۋە قېتىم سانىنى مۇۋاپىق كونترول قىلىش كېرەك.

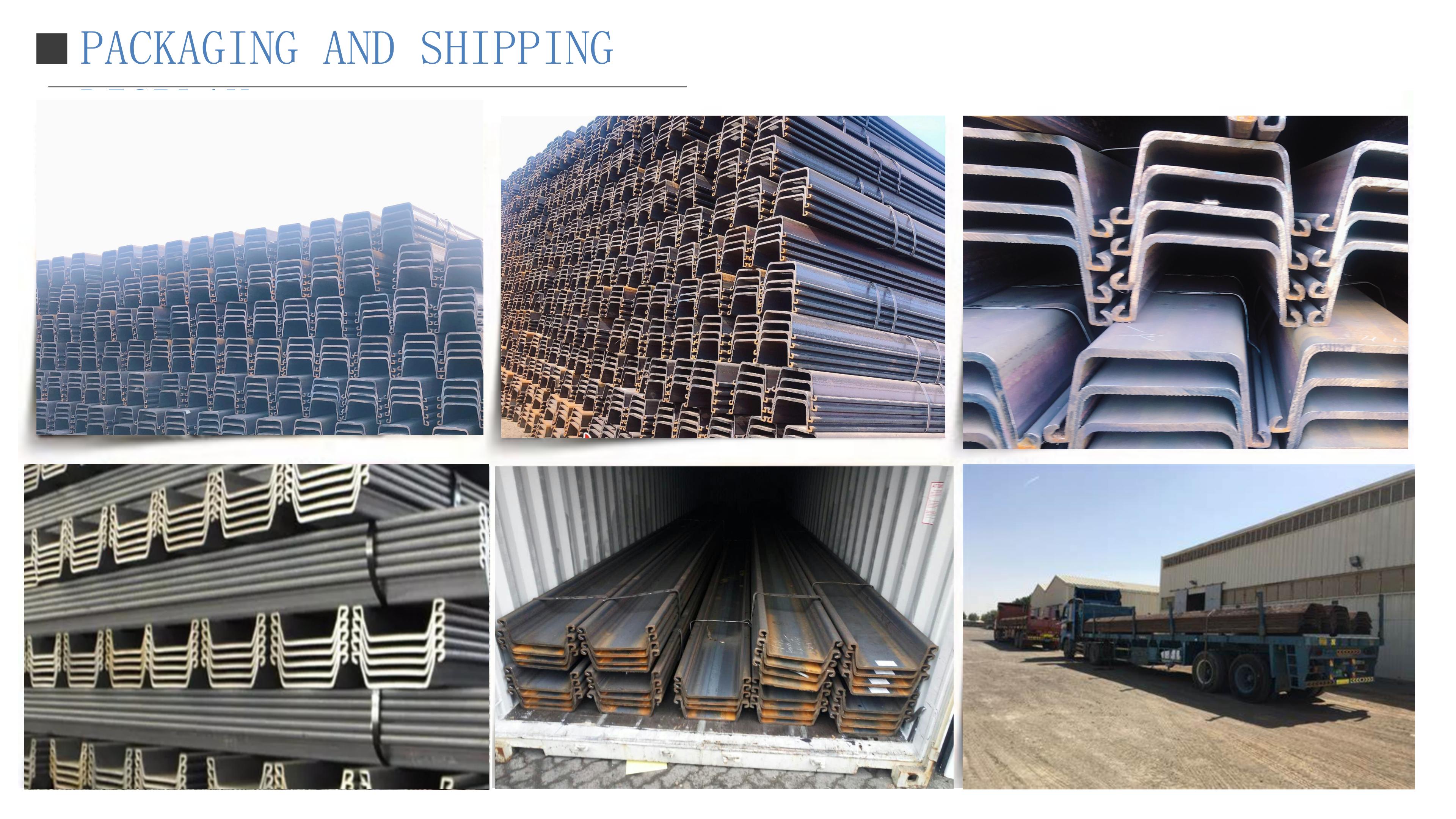

ئوراپ قاچىلاش ۋە توشۇش

1. كونتېينېر توشۇش

كونتېينېر توشۇش پولات يوپۇق تۈۋرۈكلىرىنى توشۇشنىڭ كۆپ ئۇچرايدىغان ئۇسۇلى بولۇپ، كىچىك يوپۇق تۈۋرۈكلىرىگە ماس كېلىدۇ. ھازىر نۇرغۇن شىركەتلەر خەلقئارا پولات يوپۇق تۈۋرۈك سودىسى ئۈچۈن دېڭىز كونتېينېرلىرىنى ئىشلىتىدۇ. بۇ توشۇش ئۇسۇلى ئەرزان بولۇپ، ھاۋارايى ۋە يول شارائىتىنىڭ تەسىرىگە ئۇچرىمايدۇ. قانداقلا بولمىسۇن، چوڭ يوپۇق تۈۋرۈكلىرى چوڭ بولغاچقا، كونتېينېرنىڭ چوڭلۇق چەكلىمىسىگە ماس كەلمەيدۇ، شۇڭا كونتېينېر توشۇشقا ماس كەلمەيدۇ.

2. كۆپ مىقداردا توشۇش

توپ توشۇشتا يوپۇق دۆۋىلىرىنى يالىڭاچ ھالەتتە، ئورالمىسى يوق ھالەتتە ماشىنىدا توشۇش كۆزدە تۇتۇلىدۇ. بۇ ئۇسۇل توشۇش تەننەرخىنى ئەڭ تۆۋەن چەككە چۈشۈرىدۇ، شۇنداقلا بۇزۇلۇش خەۋپىنىمۇ ئېلىپ كېلىدۇ. يوپۇق دۆۋىلىرىنى ماشىنىغا باغلاش ئۈچۈن باغلاش قاتارلىق كۈچەيتىش تەدبىرلىرى بۇ خەۋپنى ئازايتىش ئۈچۈن زۆرۈر بولۇپ، ماشىنا يۈككە بەرداشلىق بېرەلىشى كېرەك.

3. ياپلاقلىق توشۇش

ياپىلاق توشۇش ياپىلاق يۈك ماشىنىسىغا قاچىلانغان يوپۇقلارنى توشۇشنى ئۆز ئىچىگە ئالىدۇ. بۇ ئۇسۇل توپ توشۇشقا قارىغاندا بىخەتەر بولۇپ، چوڭراق يوپۇق يۈكلىرىنى سىغدۇرالايدۇ. قانداقلا بولمىسۇن، بۇ ئۇسۇل يوپۇق يۈكلىرىنىڭ ئۇزۇنلۇقى ۋە ئېغىرلىقىغا ئاساسەن تېلېسكوپ ياپىلاق يۈك ماشىنىلىرى ۋە تۆۋەن ياپىلاق يۈك ماشىنىلىرى قاتارلىق ھەر خىل ياپىلاق يۈك ماشىنىلىرىنى ئىشلىتىشنى تەلەپ قىلىدۇ.

4. تۆمۈر يول قاتنىشى

تۆمۈر يول تىرانسپورتى مەخسۇس تۆمۈر يول ماشىنىلىرىغا ئورنىتىلغان پولات يوپۇق تۈۋرۈكلىرىنى توشۇشنى ئۆز ئىچىگە ئالىدۇ. ئۇنىڭ ئەۋزەللىكى يۇقىرى سۈرئەت، نىسبەتەن تۆۋەن باھا ۋە كاپالەتلىك توشۇش بىخەتەرلىكى. قانداقلا بولمىسۇن، زىياننى ئەڭ تۆۋەن چەككە چۈشۈرۈش ئۈچۈن تۈۋرۈكلەرنى مۇقىملاشتۇرۇش ۋە توشۇش جەريانىدا سۈرئەتنى كونترول قىلىشقا ئالاھىدە دىققەت قىلىش كېرەك.

شىركەتنىڭ كۈچى

جۇڭگودا ئىشلەنگەن، ناھايىتى لەززەتلىك دۇنيا، ئەلا مۇلازىمەت، يۇقىرى سۈپەت، ئەڭ ياخشى تاماق تاللىشى

1. كۆلەم ئۈنۈمى: شىركەت چوڭ تىپتىكى تەمىنلەش زەنجىرى ۋە چوڭ پولات زاۋۇتىغا ئىگە بولۇپ، توشۇش ۋە سېتىۋېلىشنى كۆلەم باشقۇرۇش ۋەزىپىسىنى ئادا قىلىپ، ئىشلەپچىقىرىش ۋە مۇلازىمەت بىلەن شۇغۇللىنىدىغان ئومۇميۈزلۈك پولات كارخانىسىغا ئايلاندى.

2. مەھسۇلات تۈرى: مەھسۇلات تۈرىگە كەلسەك، سىز بىزدىن پولات قۇرۇلمىسى، پولات رېلىس، پولات يوپۇق تۈۋرۈكى، فوتوۋولت تىرناقلىق پولات، كرېمنىي پولات رۇلىسى ۋە باشقا نۇرغۇن مەھسۇلاتلارنى سېتىۋېلىشنى خالايدىغان ھەر خىل پولات پارچە سېتىش دۇكانلىرى بار، شۇڭا بۇ سىزگە ئەڭ ماس كېلىدىغاننى تېپىشقا ياردەم بېرىدۇ.

3. مۇقىم تەمىنلەش: تېخىمۇ مۇقىم ئىشلەپچىقىرىش لىنىيىسى ۋە تەمىنلەش زەنجىرى سىزگە تېخىمۇ مۇقىم تەمىنلەش بىلەن تەمىنلىيەلەيدۇ. بۇ، نۇرغۇن پولاتقا ئېھتىياجلىق سېتىۋالغۇچىلار ئۈچۈن ئىنتايىن مۇھىم.

4. ماركا تەسىرى: ماركا تەسىرى يۇقىرى ۋە بازىرى كەڭ.

5. مۇلازىمەت: خاسلاشتۇرۇش، توشۇش ۋە ئىشلەپچىقىرىشنى ئۆز ئىچىگە ئالغان چوڭ شىركەت.

6. باھا رىقابەت كۈچى: مۇۋاپىق باھا

پولات تاختىلار ھەققىدە تېخىمۇ كۆپ بىلمەكچى بولسىڭىز، مەن بىلەن ئالاقىلىشىشىڭىز مۇمكىن.

*ئېلخەتنى بۇ ئادرېسقا ئەۋەتىڭ[email protected]لايىھەلىرىڭىز ئۈچۈن باھا ئېلىش

خېرىدارلارنىڭ زىيارىتى

خېرىدار بىرەر مەھسۇلاتنى كۆرمەكچى بولغاندا، ئادەتتە تۆۋەندىكى قەدەملەر تەرتىپكە سېلىنىدۇ:

زىيارەت ۋاقتىنى بېكىتىڭ: خېرىدارلار مەھسۇلات زىيارىتى ۋاقتى ۋە ئورنىنى بېكىتىش ئۈچۈن ئالدىن ئىشلەپچىقارغۇچى ياكى سېتىش ۋەكىلى بىلەن ئالاقىلىشالايدۇ.

يېتەكچىلىك قىلىنىدىغان ساياھەت ئورۇنلاشتۇرۇڭ: كەسپىي خادىم ياكى سېتىش ۋەكىلى مەھسۇلاتنىڭ ئىشلەپچىقىرىش جەريانى، تېخنىكا جەريانى ۋە سۈپەت كونترول تەرتىپلىرىنى چۈشەندۈرۈشتە يېتەكچىلىك رولىنى ئوينايدۇ.

مەھسۇلات كۆرگەزمىسى: ساياھەت جەريانىدا، خېرىدارلارغا ئىشلەپچىقىرىش جەريانى ۋە سۈپەت ئۆلچىمىنى چۈشىنىشكە ياردەم بېرىش ئۈچۈن، ئىشلەپچىقىرىشنىڭ ھەر خىل باسقۇچلىرىدىكى مەھسۇلاتلار كۆرسىتىلىدۇ.

سوئاللارغا جاۋاب بېرىش: ساياھەت جەريانىدا خېرىدارلارنىڭ ھەر خىل سوئاللىرى بولۇشى مۇمكىن. ساياھەت يېتەكچىسى ياكى سېتىش ۋەكىلى ئۇلارغا سەۋرچانلىق بىلەن جاۋاب بېرىشى ۋە مۇناسىۋەتلىك تېخنىكىلىق ۋە سۈپەتلىك ئۇچۇرلارنى بېرىشى كېرەك.

ئۈلگە بىلەن تەمىنلەش: مۇمكىن بولسا، خېرىدارلارنىڭ مەھسۇلاتنىڭ سۈپىتى ۋە ئالاھىدىلىكلىرىنى تېخىمۇ چۈشىنىشىگە ياردەم بېرىش ئۈچۈن مەھسۇلات ئۈلگىلىرىنى تەمىنلەڭ.

ئىز قوغلاش: ساياھەتتىن كېيىن، خېرىدارلارنىڭ پىكىر-تەكلىپلىرى ۋە ئېھتىياجلىرىنى دەرھال كۆزدىن كەچۈرۈپ، تېخىمۇ كۆپ قوللاش ۋە مۇلازىمەت بىلەن تەمىنلەڭ.

كۆپ سورىلىدىغان سوئاللار

1-سوئال: سىزدە قانداق مەھسۇلاتلار بار؟

A1: بىز پولات تاختىلار، رېلىس، كرېمنىي پولات، شەكىللىك پولات ۋە باشقا پولات مەھسۇلاتلىرىنىڭ كەسپىي ئىشلەپچىقارغۇچىسى.

2-سوئال: يەتكۈزۈش ۋاقتىڭىز قانچە؟

A2: زاپاستىكى ماللارنىڭ يەتكۈزۈش ۋاقتى 5 كۈندىن 10 كۈنگىچە. زاپاستىكى ماللارنىڭ يەتكۈزۈش ۋاقتى زاكاز مىقدارىغا ئاساسەن 15 كۈندىن 20 كۈنگىچە.

3-سوئال: شىركىتىڭىز قانداق قىلىپ ئۈستۈنلۈكنى قولغا كەلتۈرىدۇ؟

A3: بىزدە يۇقىرى سۈپەتلىك مەھسۇلاتلار ۋە ئۈنۈملۈك مۇلازىمەتنى كاپالەتلەندۈرۈش ئۈچۈن كەسپىي گۇرۇپپىمىز ۋە ئىلغار ئىشلەپچىقىرىش لىنىيىلىرىمىز بار.

4-سوئال: سىز سودا شىركىتىمۇ ياكى ئىشلەپچىقارغۇچىمۇ؟

A4: بىز بىۋاسىتە ئىشلەپچىقىرىش ئىقتىدارىغا ئىگە زاۋۇت.

5-سوئال: سىزنىڭ پۇل تۆلەش شەرتلىرىڭىز قانداق؟

A5: 1000 ئامېرىكا دوللىرىدىن تۆۋەن زاكازلار ئۈچۈن، تولۇق پۇلنى ئالدىن تۆلىشىڭىز كېرەك. 1000 ئامېرىكا دوللىرىدىن يۇقىرى زاكازلار ئۈچۈن ئالدىن %30 T/T، قالغان قىسمىنى يەتكۈزۈشتىن بۇرۇن تۆلىشىڭىز كېرەك.

باشقا سوئاللىرىڭىز بولسا، تۆۋەندىكى ئۇسۇللار ئارقىلىق بىز بىلەن ئالاقىلىشىڭ.